INSILCURE ![]()

THE NEED

The problem of the flashover of overhead line insulation in polluted environments has been considerably reduced by the replacement of the existing, conventional insulators with appropriately dimensioned silicone rubber composite types. In substations, however, with the multitude of different ceramic insulator, bushing and housing designs present, replacement is not practical - yet the need for a permanent, maintenance-free solution to pollution flashover remains. INSILCURE has been developed to provide such a solution.

THE INSILCURE ENGINEERED APPROACH

The INSILCURE system comprises three distinct parts, namely,

· The detailed audit of all insulation in the yard to fully define the characteristics of every insulator and assess its suitability to operation under the existing ambient conditions

· For all those insulators identified as being under-dimensioned for the pollution severity of the site, the design and application of INSILSHED htv silicone rubber shed extenders to create profiles and creepage distances which will ensure reliable, maintenance-free performance

· The coating of the insulators and shed extenders with INSILCOTE rtv silicone rubber to provide the insulator surfaces with uniform hydrophobic properties and thus further enhance their flashover resistance.

THE INSILSHED EXTENDERS

The INSILSHED extenders are made of true htv silicone rubber material with its inherent hydrophobic characteristic and tracking, erosion and UV resistance. Even in the uncoated state, therefore, the sheds are capable of operation in the most extreme environments. They are attached to the insulators by means of an rtv silicone rubber adhesive.

The dimensional design of the extenders and how many and where they are applied to each insulator is critical to the long term performance and is based on over 30 years' experience in ceramic and polymeric insulation design. All key geometric parameters such as creepage distance and shed spacing-to-projection ratios are given due consideration. The upgraded insulators comply fully with the profile requirements of IEC 60815.

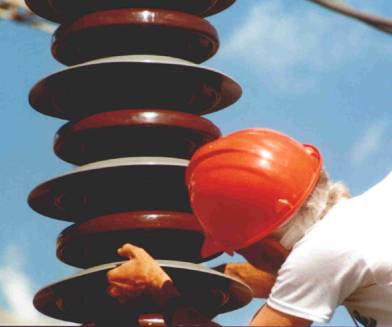

A technician positioning the INSILSHED shed extenders

THE INSILCOTE COATING

The INSILCOTE coating is the result of a joint development project between Mace Electrical Technologies and the Electric Power Research Group of the University of the Witwatersrand and has been in use in the most harsh environments since its introduction in 1991. With its extremely hydrophobic characteristic, the formation of a continuous wet conductive insulator surface is prevented. Even when severely polluted, the low molecular weight silanes present in the coating diffuse into the contaminating layer maintaining the water repellency and inhibiting leakage current activity.

The coating provides a vast improvement to insulator performance and in many cases will, on its own, represent a permanent solution to pollution flashover. The reliability of any substation, however, is dependent on the weakest insulator in the yard. For those units which are grossly under-dimensioned for the prevailing conditions, the combination of the shed extenders and coating ensures that all insulators are of adequate standard and that acceptable system security is achieved.

Old cap-and-pedestal posts before and after INSILCURE upgrading.

Coating life is dependent on the design of the insulator to which it is applied relative to the severity of the environment in which it is located. By increasing both the quality of the profile and quantity of the creepage distance to a suitable level with INSILSHEDS, not only are flashovers prevented, but the stress on the coating is reduced and, consequently, its life can be virtually indefinite.

Although requiring greater initial capital, the life cycle cost of the INSILCURE system is significantly less than the undertaking of regular insulator maintenance. More importantly, the risk of flashover with the INSILCURE system is considerably lower.

With an insulator washing programme, the cleaning interval needs to be fairly short and thus numerous outages are required. If live-line washing is adopted, the danger of precipitating flashovers on the surrounding insulators owing to wetting by overspray constitutes a real danger. Uneven wetting of large diameter porcelains, such as current transformers, or surge arresters, for example, can also cause breakdown.

However, the main drawback of a washing approach is establishing the correct timing of the operation. Unless complex condition monitoring, involving some form of artificial wetting, is introduced, unseasonal rain or fog can cause unexpected flashover. Further, in areas subject to "instantaneous" pollution, e.g. conductive fog conditions, washing is totally ineffective. The upgraded INSILCURE insulator is always prepared for the unexpected climatic event and, with its inherent surface hydrophobicity, will shrug off the effects of marine salt fogs and acidic mists.

The application of silicone grease, with its water-repellent properties and ability to encapsulate contaminants, can permit a longer maintenance interval than washing. The highly labour intensive and expensive task of replacing the grease, though, makes this by far the most costly option. Add to this the associated long outages required, possible insulator flashover or damage if the layer is not renewed in time, potential health risks and environmental disposal problems, and greasing is not at all attractive.

Shed extenders, used on their own, can serve to increase the creepage distance and/or improve the insulator profile but in-depth knowledge of insulator design is required to ensure their correct application. The main disadvantage of extenders is that the different surface properties of the ceramic insulator and the polymer extender can create severe voltage distortions resulting in partial discharges and flashover. With the INSILCURE system, uniform surface characteristics are realised.

· The INSILCURE system represents a permanent pollution flashover solution for substations, eliminating the unreliability and limited effectiveness of washing programmes and the extremely high economical and environmental costs of greasing

· The INSILCURE system identifies the "weak links" in the yard and elevates the quality of all the insulators to an acceptable standard

· The INSILCURE system provides the insulators with a uniform and highly hydrophobic surface characteristic preventing flashovers induced by both pre-deposited pollution layers and instantaneous conductive fog contamination.

CIGRE PAPER ON ELIMINATION OF POLLUTION FLASHOVER IN SUBSTATIONS

DOWNLOADABLE BROCHURES/PAMPHLETS