"REDEYE" THERMAL INSPECTION SERVICE

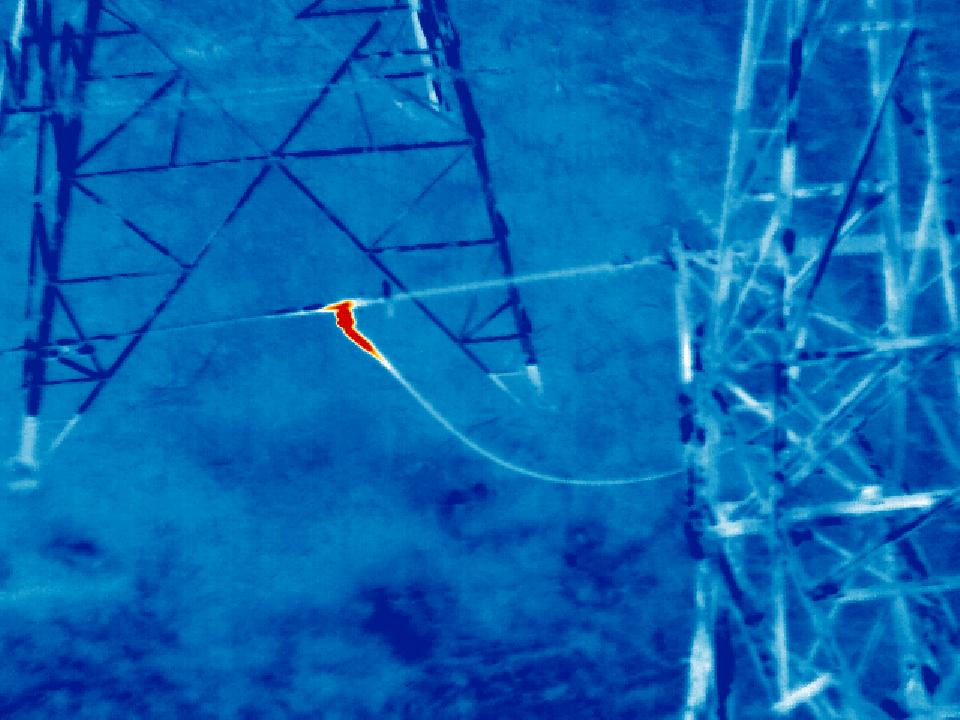

Mace Technologies have been undertaking the detailed thermal inspection of high voltage installations and equipment since their establishment in 1990. Specialising in the study of transmission and distribution systems, Mace have held long term contracts for the infrared scanning of all of Eskom's Transmission Stations in the Rand, Kwa-Zulu Natal and Eastern Cape areas. Overhead line examinations, undertaken from a helicopter, are also offered.

Mace Technologies were the developers of a technique to detect deteriorating clamps on overhead railroad equipment from a locomotive. This condition monitoring procedure has been adopted by rail authority, Spoornet, on a national basis.

Key to the success the Company has enjoyed in the thermal inspection field, is the combination of both the infrared thermography and high voltage expertise available. This is vital to achieve meaningful results and ensure system security.

INSPECTION METHOD

The method employed by Mace Technologies for infrared thermal inspections is based on the philosophy that the condition of each and every current-carrying component must be both (a) properly examined and (b) recorded.

Although, with today's infrared imagers, very hot spots can be detected from a distance, to reliably locate all potential failures, particularly faults internal to items of equipment, close viewing of the item and comparison of its radiation with those on other phases and the conductors to which it is attached is necessary.

Further, should a failure occur, it is important for investigators to be able to see the state of the component at the time of the previous inspection. The entire infrared scan is therefore recorded on video tape. If a record is made of the hot spots only, valuable information may be lost.

INSPECTION EQUIPMENT

The instrument employed is a Jenoptik Variocam HiRes Research 1.2 Mega camera which is of the uncooled focal plane array (FPA) type, boasting an extra high resolution (1280 x 960 pixel) and operating in the 8 to 14 micron spectral range. The images are stored on an internal flash card. Where thermal elevations are detected, the recorded images can be studied in detail by means of the Jenoptik “VarioAnalyze” and “VarioCapture” thermal analysis software.

THERMOGRAPHER

No matter how sophisticated the instrument, if the thermographer does not have a thorough understanding of what the camera sees and how this is affected by variations in emissivity, camera filtering, atmospheric absorption, etc., totally erroneous conclusions may be reached.

Apart from being capable of accurate interpretation of the images displayed, the Mace thermographers are experienced in substation operation and equipment and thus well qualified to identify the precise position of the fault, to assess its severity and to recommend appropriate corrective action.

DOCUMENTATION

All equipment and components are video taped in the infrared spectrum. This not only provides the thermal image of the item, but the time, date substation/line/distribution board name, temperature readout and emissivity settings are permanently displayed. In addition to the image and on-screen graphics, the thermographer's spoken commentary can be heard on the sound track. A complete verbal description of the situation is thus available for the entire installation and the tape represents the most comprehensive record possible.

For each hot spot located, a Fault Report Sheet is completed. This sheet gives the precise position of the fault, the nature of the defect, its probable cause and the corrective action recommended. A tape reference is also provided so that personnel can fast-forward the video tape to this reference and obtain the full details of the problem shown from various angles with the thermographer's verbal on-site description of the situation.

The degree of urgency indicated on the Fault Report Sheet is, in general, related to the amplitude of the temperatures and temperature differences but, as these are significantly influenced by wind, solar radiation and load, they are interpreted more broadly. Other factors considered are typically the strategic nature of the item of equipment and the risk of damage to other equipment should the item in question fail.

The documentation provided is designed to

· communicate as efficiently as possible, to the most appropriate persons, the need for corrective maintenance on specific apparatus and components

· provide a comprehensive record of the results obtained and the state of the installation at the time of the inspection

· permit the detailed computer analysis of the thermal characteristics of the apparatus where necessary.

Additional customised documentation, such as Management Reports which provide an overall view of the condition of the system as a whole can also be prepared.

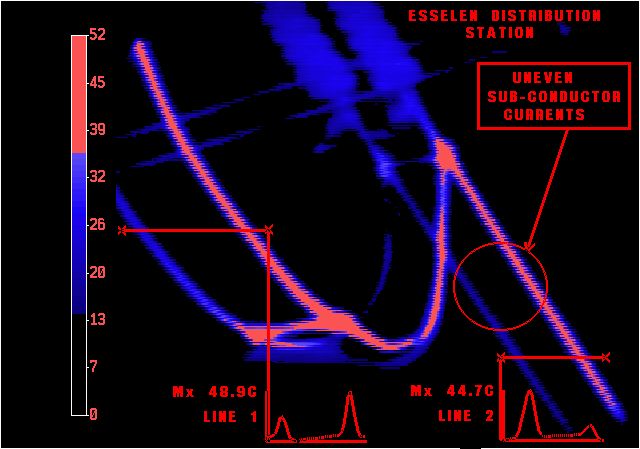

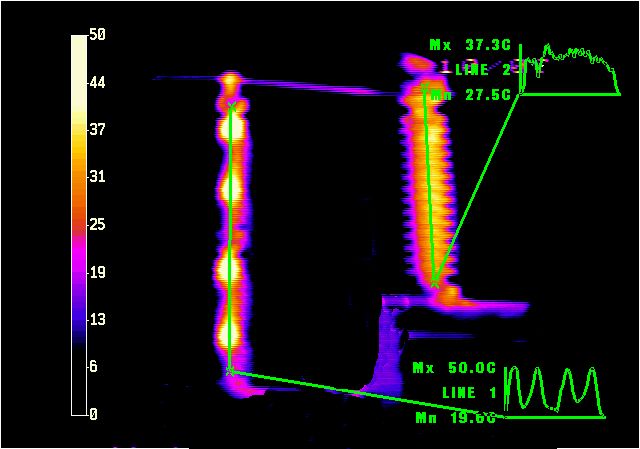

FAULT ANALYSIS

In substations, the cause of a temperature elevation is usually obvious and is often the result of a bolted current-carrying clamp which has lost contact pressure due to creep of the conductor. On occasion, however, the source of the heat may not be clear and may indicate, for example, a more serious fault internal to a piece of apparatus. A more detailed and sophisticated analysis of the image may then be necessary to establish the cause, possible consequences and appropriate corrective action. For this task, Mace Technologies are equipped with the specialised computer and "frame-grabber" hardware and "infraSOFT" thermal analysis software. This permits a thorough study of the recorded images and can provide thermal distributions, temperature profiles, isothermal views, etc. The client can thus be assured that the results of the "Redeye" inspections are properly interpreted and meaningful.